Outrageous Info About How To Rebuild A Engine

For the sbc 350.more.more never rebuilt.

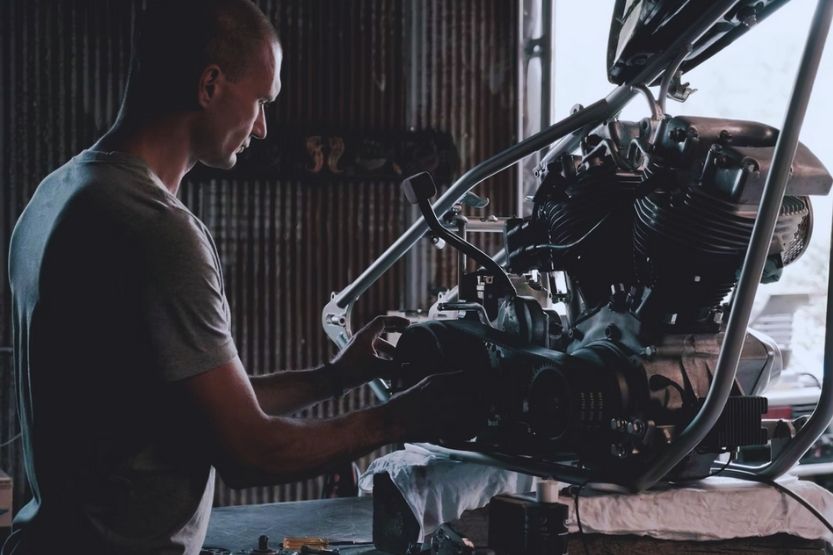

How to rebuild a engine. How to rebuild an engine for beginners: These new internal goodies are crucial for giving your engine the performance upgrade it so much needs. In addition to a proper workspace, you will also need to rent or borrow an engine hoist to pull and install the engine.

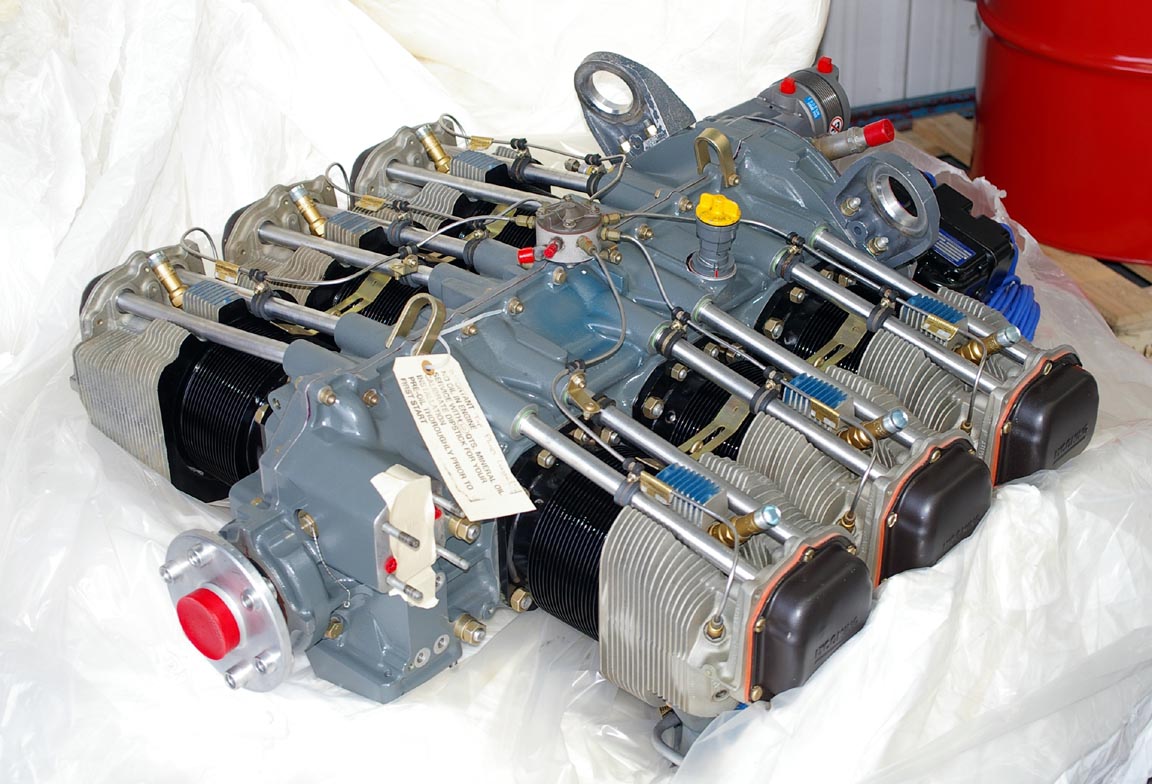

First, we will learn what is an engine rebuild and how do you can tell if your engine is due to be rebuilt. Lift the engine back into the tractor: What do you need to rebuild an engine?

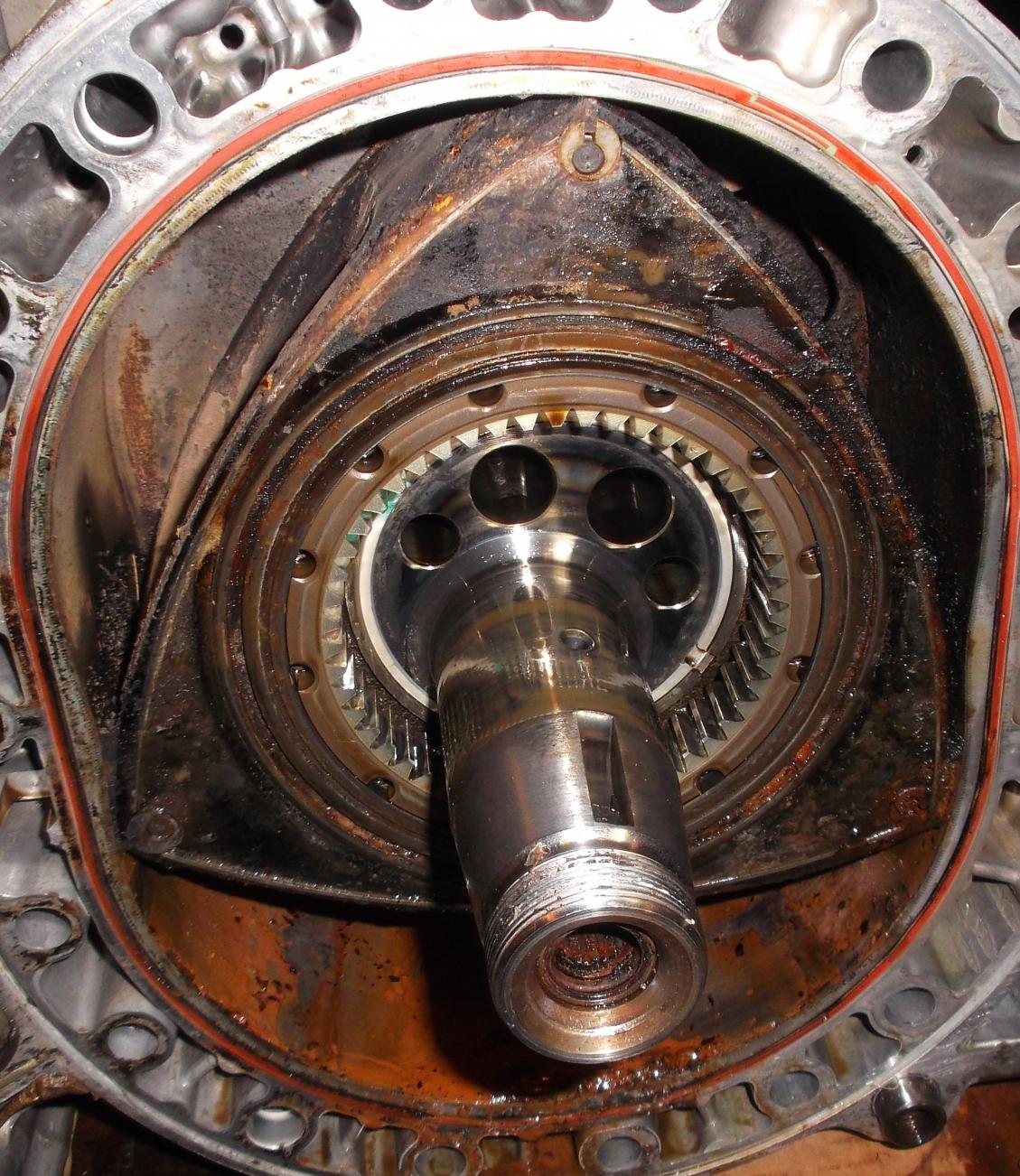

Install new pistons, bearings, seals, rings, and gaskets. Assembling your own engine can be very rewarding for any automotive enthusiast or professional. Preparation before embarking on your engine rebuilding journey, gather all the necessary tools, equipment, and resources that you’ll need.

You need gumption to rebuild an engine. In this article, we will take a look at why engines are rebuilt, what is done to rebuild an engine, and some signs that your car might benefit from a rebuild. 16k 1.7m views 5 years ago #smallenginerepair #tarylfixesall #carburetor in blademan & throttle and the orbital ignition module, taryl goes over the proper steps.

January 13, 2024 by lambda geeks welcome to the world of engine. Compare the pros and cons of rebuilding vs. Essential tools for rebuilding a car engine include wrenches, an engine hoist, an engine stand, a torque wrench, a gasket and seal kit, cleaning supplies, a micrometer, safety.

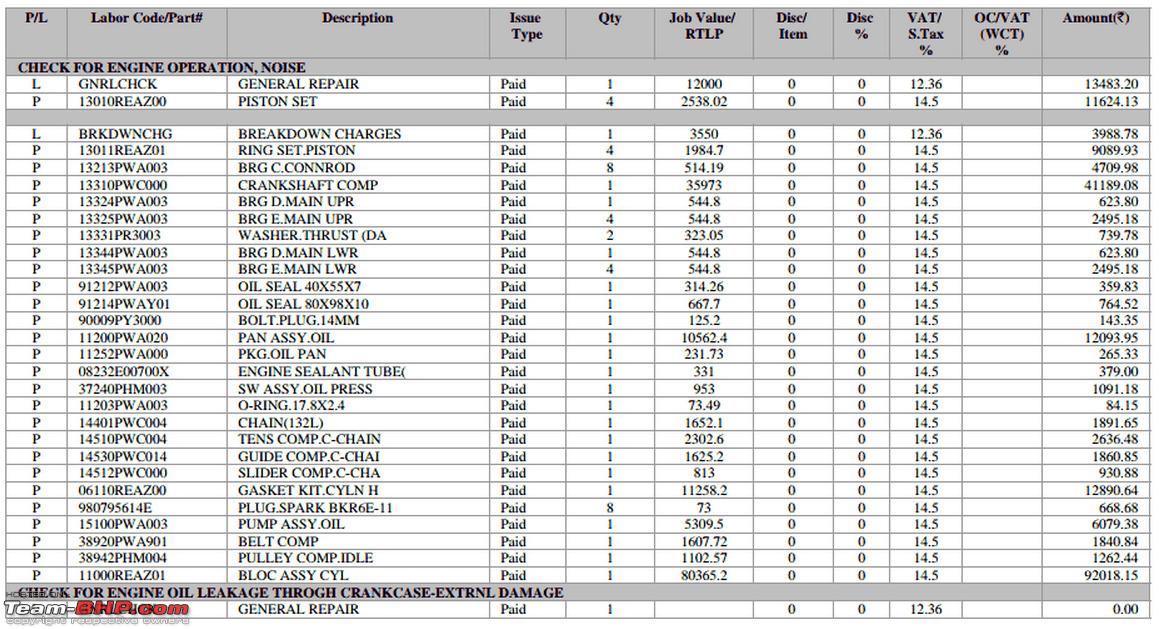

Learn to build engines with confidence. The price depends on what type of car you are driving and where you take it to get rebuilt. The final step in rebuilding your ford 8n engine is to reinstall it into the tractor.

If the compose file specifies an image name, the image is tagged with that name, substituting. This gives you all the tips and tricks on. Perform a thorough inspection and testing of the rebuilt engine.

Yard bill to get the engine in and out: The task is complex enough that if you don’t feel you’re not. Once the engine is out of its bay, an engine.

Then we will cover everything you need to know when it. That being said, if price is your primary criterion for deciding between a rebuilt or remanufactured engine, a rebuild is the way to go. $5000 if relatively easy installation and $10,000 if a tough job involving major disassembly and rebuild of surrounding cabinetry.

On average, rebuilding an engine costs $2,000 to $4,500. Reassemble the engine, following the manufacturer’s specifications and torque settings. Place all components into a.